Censtar Vapor Recovery in filling stations

Fuel Dispenser Available OptionsVapor Recovery in Unloading(Stage 1 recovery)

Vapor Recovery in Filling Station( Stage 2 recovery)

Vapor storage and condensing system: also known as Stage 3 recovery

Effect Examination of Vapor Recovery in Filling Station( Stage 2 recovery)

Easy ways to get the answers you need.Perfectly customizable your fuel dispenser and gas station!

description

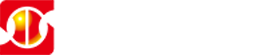

Vapor Recovery in Unloading :

also called Stage 1 recovery. It is a balanced system in which the oil is discharged from the tank truck to the tank and the vapor in the tank are returned to the tank truck under the balanced pressure.

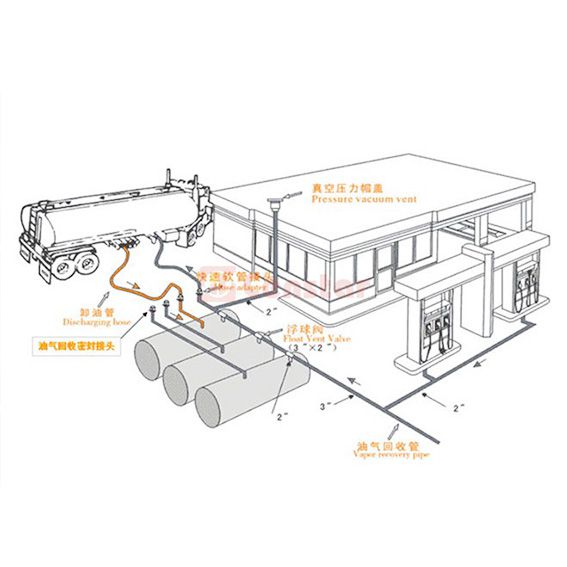

Vapor Recovery in Filling Station( Stage 2 recovery):

It is a vacuum-assisted vapor recovery system. The principle is that when the tanker refuels the car, the vapor recovery pump works to pump the vapor emitted from the car's tank back into the tank through the holes in thin hose of nozzles.

Vapor storage and condensing system: also known as Stage 3 recovery, it is designed for the tank management system of gas stations. When the tank pressure becomes high, the excess vapor is converted into gasoline, and when the pressure becomes low, air is pumped into the tank 。

Effect Examination of Vapor Recovery in Filling Station( Stage 2 recovery):

Three important Parameters in effect examination : system tightness 、vapor recover line liquid resistance and vapor liquid ratio.

System tightness: Airtightness of vapor recovery system under certain gas pressure

Liquid resistance: the resistance of condensate liquid when it is trapped in the vapor line or when gas passes through the line due to other reasons

Vapor liquid ratio: The ratio of the volume of vapor collected during refueling to the volume of gasoline into the tank.

parameter

Censtar Vapor Recovery in filling stations

Parts in Stage 1 vapor recovery

Also called unloading vapor recovery,The working principle is equilibrium

following are the main parts:

Unloading ports subassembly

Quick connector

3-way float valve

Vacuum cap

Stage 2 vapor recovery

1、working principle

The stage 2 recovery system is used to recover the vapor produced by the tank during refueling。

The principle is to close the whole system and use the double-channel refueling nozzles and connecting pipe to pump the vapor produced during refueling back to the tank to balance the pressure drop caused by refueling process.

Stage 3 vapor recovery

1、 Vapor storage and condensing system: also known as Stage 3 recovery, it is designed for the tank management system of gas stations. When the tank pressure becomes high, the excess vapor is converted into gasoline, and when the pressure becomes low, air is pumped into the tank

2、working principle

When the air pressure in the underground storage tank rises to the set value of pressure,The system starts running automatically;

The mixture of vapor and air is compressed, condensed, and in the process of condensation, Most of the gas-phase vapor condenses into liquid phase gasoline, which is separated by gas-liquid separator Into underground tanks

Residual gas mixture into the VOC membrane module into the next phase separation, membrane material Coated on the surface of the active polymer material, it can divide the gasoline molecules out of the air, It leaves and flows into a storage tank, partially condensing into gasoline on the return journey, The air molecules continue on until they are released into the atmosphere as clean air; As the system works, the pressure in the tank gradually decreases, when the induction pressure is lower than setting the value, the system will automatically stop running and enter standby state.

Related Products

Related cases

Inquiry

Thank you for your interest in Censtar. If you want to learn more about our Gas station equipment, Contact us Now to find out what we can do for you !